Access the essential membership for Modern Managers

Organizations continually strive for lean and efficient operations.

Your company may ask you to find opportunities for lean improvements in your department or area so that you can deliver the same value to the customer at lower cost to your organization.

However, identifying these opportunities can be a challenge.

One way of doing this is by using Value Stream Mapping, a lean manufacturing technique which you can use to analyze your current processes and identify areas for improvement. In this article, we'll explore Value Stream Mapping (VSM) in more detail, and how you can use it to make your organizational processes more efficient.

What Is Value Stream Mapping?

Value Stream Mapping (VSM) is a lean manufacturing technique, which allows you to create a visual map of the end-to-end process of a product or service.

VSM was originally used at car manufacturer Toyota, where it was known as "material and information flow mapping." Mike Rother and John Shook then developed Toyota's ideas in their 1999 book, "Learning to See," where it was referred to as Value Stream Mapping. [1] VSM is now widely used in a variety of industries as a way of identifying improvement projects.

The basic idea behind Value Stream Mapping is that, if an underlying process is right, the outcome will be reliable. To get the process right, you have to understand the sequence of activities that provide value to your customers.

VSM enables you to visually map how information and materials flow through all of the activities involved in a process. For example, from the time an order is placed to the time the product or service is delivered. The starting point is customer needs, where the map shows how and when information is received. The end is when the product or service is delivered to the customer, with the map showing how decision-making and communication processes affect the whole flow.

By looking at your process from start (receiving orders or forecasts) to finish (warehousing or distributing the product), you can clearly identify steps where no real value is added or where there's a bottleneck, and eliminate these types of waste. Your original Value Stream Map becomes the baseline for improvement initiatives that eliminate no-value, wasteful activities.

A Value Stream Map doesn't need to be overly detailed, but it should contain enough information about the flow of information and physical products to help you to effectively identify problems and potential improvements.

Note:

Value Stream Mapping shouldn't be confused with Value Chain Analysis or Porter's Value Chain. These tools look at the strategic part of what your company offers its customers. They ask you to evaluate whether your final product can be improved, so that you add more value to your customers, and thus increase your appeal. By contrast, VSM looks at how the product is made – to ensure that each step adds value to the overall process.

Also, don't confuse VSM with flow maps or flow charts. Value Stream Maps look at processes at a higher level than typical process flow maps or flow charts. Traditional process flow charts are typically used to examine one specific process in detail (for example, how a customer complaint is handled). Producing a VSM helps you to identify what the key value-added activities are, so you can eliminate activities that are inefficient or wasteful.

How to Create and Use Value Stream Maps

The aim of Value Stream Mapping is to build up a picture of how items (such as materials, designs, or customer needs) flow through the value stream in your organization – from raw materials and inputs through to the customer's end product.

Value Stream Mapping is best applied to processes that are reasonably routine and standardized. Manufacturing companies are obvious examples of these. But any organization that delivers a standard set of products or services will likely benefit from applying VSM.

However, Value Stream Mapping is unlikely to be useful where work processes change continuously or where bespoke products are delivered, because the flow may change with each customer or project.

You can use Value Stream Mapping in your organization by following these steps:

1. Identify the Product or Service You Want to Map

First, you need to identify the process that you want to make leaner and more efficient.

It's important to define the scope of your map in this step. So, start by identifying the start and end points, and make sure that you map from one end of the process to the other. This will allow you to identify where blockages and non-value activities are.

You also need to identify which part of the overall process you need to look at. For example, if the amount of profit you're generating from each customer order is falling, then you may want to look at how an entire order is fulfillled. If the volume of orders is falling, then you may want to look at the sales process in more detail.

2. Draw Your Current Value Stream Map

To help you draw the map, get feedback from the key stakeholders involved in the process. Include people who manage and support the various parts of the value stream. It's vitally important here to include people who actually do the work, and not just the managers or team leaders – otherwise you risk creating a VSM that shows what should happen, rather than what actually happens.

Then gather the following date to complete the map:

- Brainstorm who is involved, both internally and externally; what is needed to deliver the product or fulfilll the customer need; and the tasks or activities that go into producing the products.

- Put these tasks in order, as much as possible, and include costs and actual working time for each task to build up a picture of average performance for each task (and – ultimately – for the entire, end-to-end process).

- Assess the length of time it takes to complete each stage of the process – for example, the length of time a task sits in someone's in-tray – to help you identify delays or bottlenecks.

Let's say we want to create a Value Stream Map that looks at the end-to-end process of fulfillling an online product order for a customer. Tasks involved in this process would include:

- Order entry and processing.

- Supplier liaison.

- Inventory management.

- Order picking.

- Packaging.

- Shipping.

Depending on your operations, any of these tasks could be the subject of its own Value Stream Map – that's why defining scope is so important.

Here's how we could organize the tasks in our example:

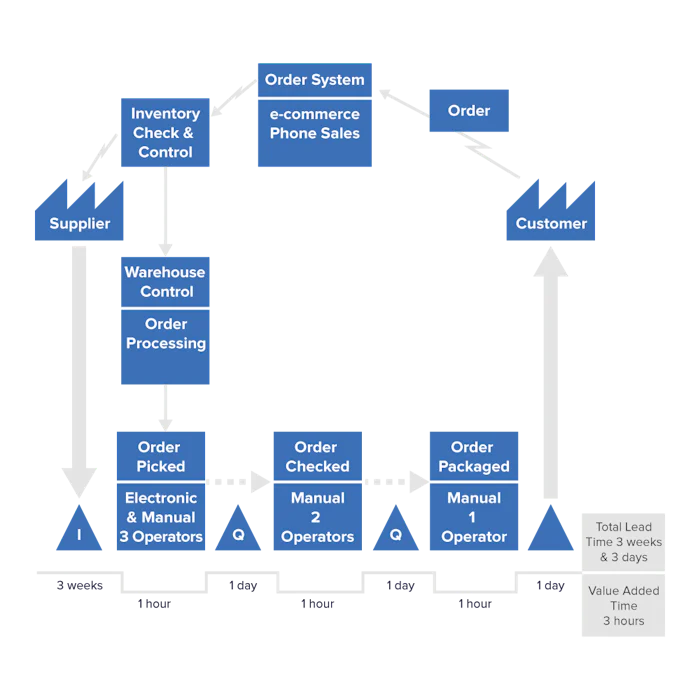

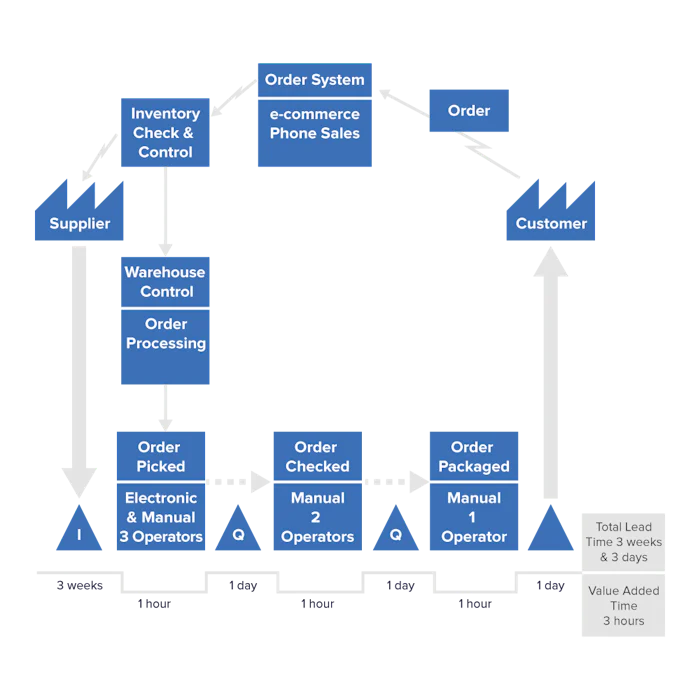

Figure 1. Example of a Value Stream Map for an Online Product Order and Delivery

Originator of Figure 1 unknown. Please contact customer.helpdesk@mindtools.com if you know who the originator is.

In the diagram above:

- Blue symbols represent customer and supplier.

- Blue boxes represent the activities involved in the main process steps.

- Triangles with "I" represent stored inventory.

- Triangles with "Q" represent quality checks.

- The thin gray arrows represent information flow between steps.

- The thick gray arrows and dotted gray arrows represent a push or move from one step to another.

- At the bottom of the graph, the timeline is shown. An upline represents processing time, while a downline represents value added time.

- The gray boxes show the total lead time and the value added time (this is the time spent that adds value to the product).

Note:

There are a variety of software programs and apps you can use to draw Value Stream Maps, many of which include the set of shapes typically used to represent various parts of the process. You may or may not want to use these, but it's important to map your process clearly, and it's also important to ensure that everyone understands what the symbols you use mean, so be sure to include a diagram key as well.

3. Assess Your Current Value Stream

In this step, you analyze whether each activity in the process is adding value. This is where you can identify opportunities to create a leaner more efficient process.

Value-add activities can change an item in your Value Stream Map, and make it worth more to the customer. Car assembly is a great example of how this works: as the car body moves along the production line, more and more pieces or assemblies are added, making it more complete. Eventually, it becomes a fully operational vehicle that people will buy. Each step adds value (although clearly the most value is added when the final component is installled!).

As you assess your value stream, consider the following points:

- At each point in the map, ask yourself, “Does this activity add value?”

- Identify your value-add points.

- Identify your no-value-add points (for example, places where material is stored, redundant or excessive paperwork, and places where there are long lead times).

- Determine which no-value-add points are still necessary (for example, for meeting regulatory requirements, addressing other compliance issues, and ensuring worker safety).

4. Create a "Future State" Value Stream Map

Map how you want your improved process to look in the future. How will the process work after you've eliminated the waste you identified in the previous step?

To do this, consider the following:

- Assume that anything is possible. Consider how you would structure the process if you were starting the business today with unlimited capital.

- Ask yourself what your leanest competitor would do.

- Look for similar activities, and see if there's a way to group them.

- Identify bottlenecks and critical events.

- Look for ways to simplify activities that are complex.

- Confirm that each activity in your process actually adds value for your customers.

Look for common forms of waste as well. For example:

- Moving product/materials inefficiently.

- Using equipment and people unnecessarily.

- Keeping too much or too little inventory.

- Performing inefficient quality checks.

- Stockpiling finished goods.

- Adding features or overly detailed quality checks that the customer does not value.

Here are some of the opportunities for improvement we could identify for our example of fulfillling an online order:

- Eliminate redundant approvals or move them earlier in the process to prevent unnecessary work.

- Improve the flow of information (paper or electronic).

- Restructure the warehouse operations for efficiency.

- Update the inventory control system.

5. Create a Plan to Implement the Desired State

When you have identified your key objectives, you can develop a plan for change. Do this by working through the following key points:

- Use the VSM to communicate your goals and objectives.

- In your VSM team, include people who are involved in the process to improve employee buy-in.

- Talk frequently about lean and efficient operations so that it becomes part of your corporate culture.

- Look for ways to reward efficient work and efficiency suggestions.

6. Implement the Plan

Once you have a goal in mind to improve your value stream, use lean processes to manage implementation – such as Kaizen, Kanban, and Just In Time. Remember, though, that the time you invest in VSM will pay off only if you follow through with the implementation plan.

7. Review and Repeat

Review your results carefully to see where you've made improvements and whether they are actually resulting in efficiencies. Then, apply what you've learned to other areas of your business.

Key Points

Value Stream Mapping enables you to create a visual map of your key organizational processes. It can be used to illustrate the links between different stages of a process, as well as the time and volumes involved in each.

You can use VSM to gain a better understanding of how the different activities in a process fit together – and you'll be able to create an action plan for eliminating waste and, ultimately, saving costs.

You can create your own Value Stream Map by following these seven steps:

- Identify the product or service you want to map.

- Draw your current value stream map.

- Assess your current value stream.

- Create a "future state" value stream map.

- Create a plan to implement the desired state.

- Implement the plan.

- Review and repeat.

References[1] Rother, M. and Shook, J. (1999). '

Learning to See,' Brookline: The Lean Enterprise Institute.